Polycarbonate resin/Polyca (PC)

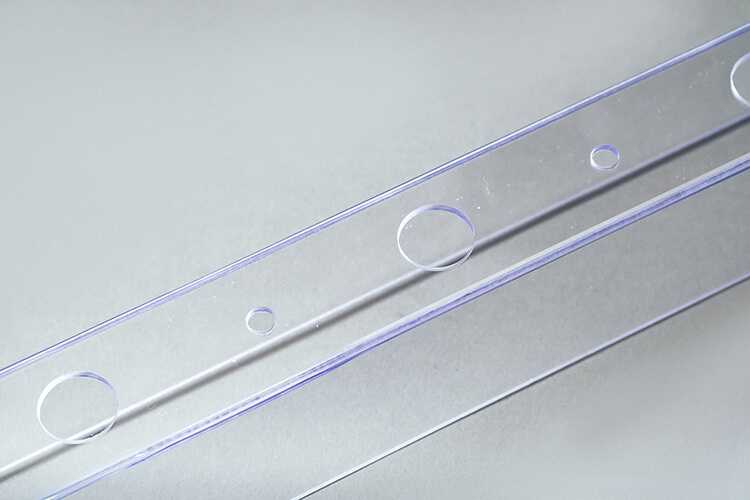

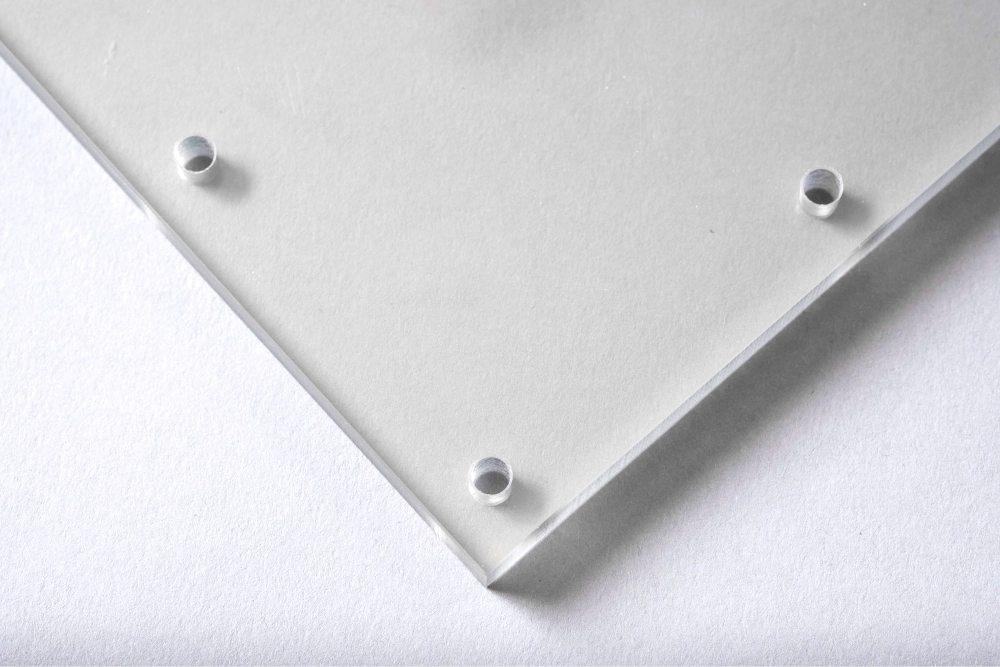

Polycarbonate resin is one of the engineering plastics, and is classified as a thermoplastic resin.

It is characterized by its excellent impact resistance and transparency comparable to that of glass. It

also has excellent properties such as heat resistance, weather resistance, cold resistance, mechanical strength, and electrical properties, and is used in a variety of fields, not only in industrial products but also in everyday items.

Thermoplastic resins and others

ABS/Vespel/PS/PET/Unilate/Silicon Rubber/PP/PEEK/MC Nylon/POM/PE/Teflon

Features

- Excellent impact resistance (approximately 30 times that of acrylic, approximately 200 times that of glass)

- Heat resistant (heat resistant temperature: 120℃)

- Excellent weather resistance and cold resistance (suitable for outdoor use)

- High transparency

Physical property table

General grade plate material (excerpt from manufacturer’s data)

*Please scroll horizontally to view.

| Specific gravity | ASTM D 792 | 1.2 | |

|---|---|---|---|

| Rockwell hardness | ASTM D 785 | R119 | |

| Tensile strength | ASTM D 638 | MPa | 63.7 |

| Stretch | ASTM D 638 | % | 100 |

| Compressive strength | ASTM D 695 | MPa | 81.3 |

| Bending strength | ASTM D 790 | MPa | 93.1 |

| Flexural modulus | ASTM D 790 | MPa | 2,350 |

| Izod impact strength | ASTM D 256 | J/m | 780 |

| Deflection Temperature under Load | ASTM D 648(1.82MPa) | ℃ | 140 |

| Embrittlement temperature | ASTM D 764 | ℃ | -135 |

| Linear expansion coefficient | ASTM D 696 | 10-5/℃ | 7.0 |

| Thermal Conductivity | ASTM C 177 | W/(m K) | 0.19 |

| Heat transfer coefficient | ASTM C 177 | W/(㎡ K) | 5.5 |

| Heat transfer coefficient | ASTM C 177 | W/(㎡ K) | 5.5 |

| Specific heat | X103J/(kg K) | 1.26 | |

| Refractive index | ASTM D 542 | 1.59 | |

| Total light transmittance | ASTM D 1003 | % | 89 |

| Breakdown Voltage (AC) | ASTM D 149 | KV/mm | 14.8 |

| Volume resistivity | ASTM D 257 | Ωcm | 3.8X1016 |

| Dielectric constant | ASTM D 150 | 2.9 | |

| Arc Resistance | ASTM D 495 | sec | 10-11 (stainless steel electrode) 121 (tungsten electrode) |

- *The data in the physical properties table are representative examples of measured values.

- *The data in the physical properties table is the measured value for a plate thickness of 3.0 mm.

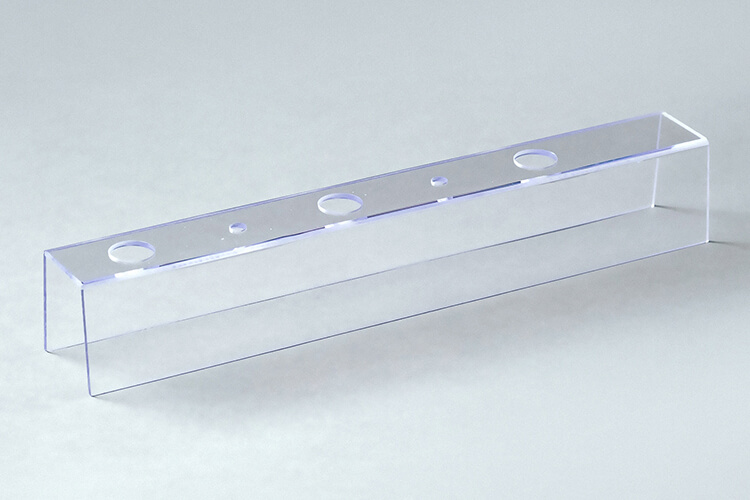

Application example

- Various machine covers

- Roofing materials

- Machinery Parts

- Diffusion prevention cover

Major manufacturers

- Takiron C.I. Co., Ltd.

- Sumitomo Bakelite Co., Ltd.

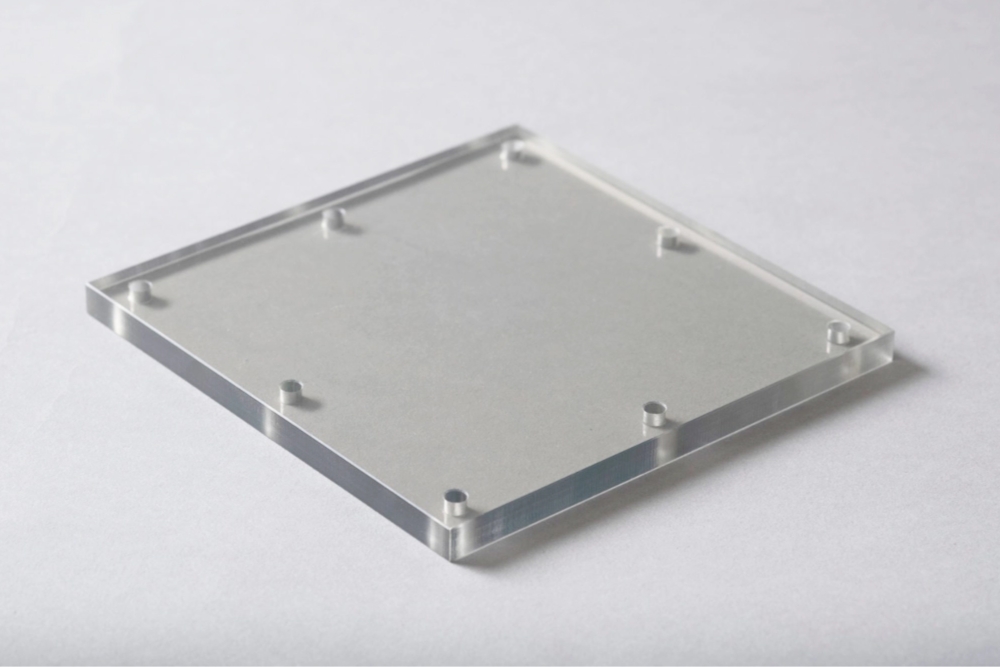

Acrylic resin/PMMA

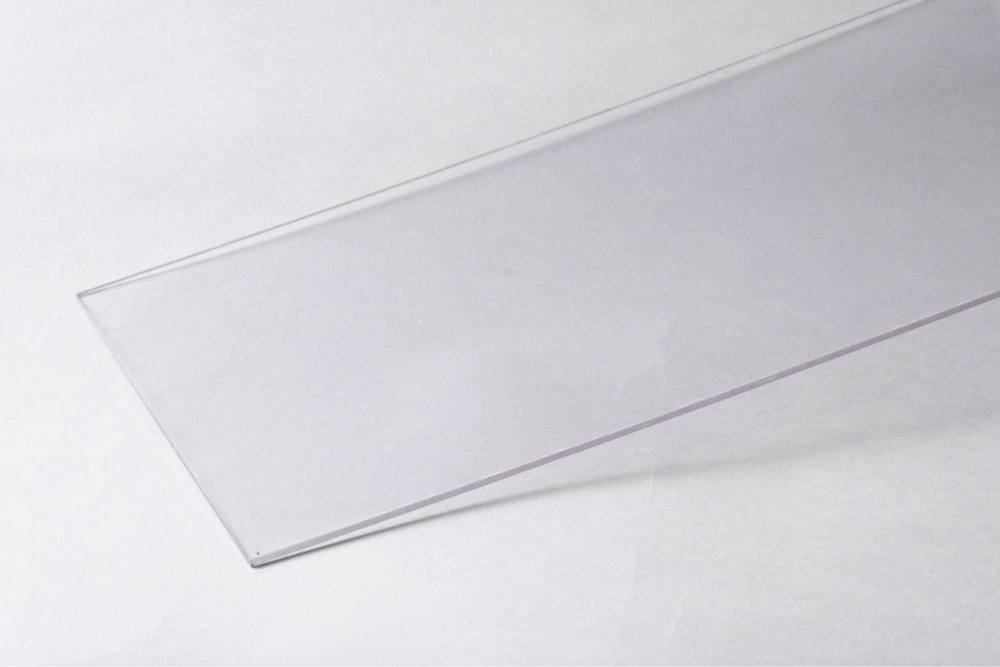

Acrylic resin is one of the general-purpose plastics, and is classified as a thermoplastic resin. It is characterized by high transparency, and has excellent impact resistance and weather resistance, and is used in a variety of fields. In terms of processability, it can be bent, bonded, cut, etc., making it a resin material with a high degree of freedom.

Features

- It has excellent weather resistance, impact resistance, and optical properties.

- It has excellent electrical properties.

- Easy to mold.

Physical property table

General grade plate material (excerpt from manufacturer’s data)

*Please scroll horizontally to view.

| General characteristics | Densityaa),b) | JIS K 7112, A method, C method, D method | g/cm3 | 1.19 |

|---|---|---|---|---|

| Optical properties | Refractive index, nD23 | JIS K 7142, A method | 1.49 | |

| Total light transmittancea) | JIS K 7361-1 | % | 93 | |

| Hazea) | JIS K 7136 | % | 0.5 | |

| Mechanical Properties | Tensile strength | JIS K 7161-2/1B/5 | MPa | 74 |

| Tensile strain at break | JIS K 7161-2/1B/5 | % | 4.5 | |

| Tensile Modulus | JIS K 7161-2/1B/1 | MPa | 3200 | |

| Bending strength | JIS K 7171 | MPa | 120 | |

| Charpy impact strength(unnotched) | JIS K 7111-1/1fU | KJ/m2 | 17 | |

| Rockwell Hardness | JIS K 7202-2, M scale | 98 | ||

| Thermophysical properties | Deflection Temperature under Load | JIS K 7191-2, A method | ℃ | 90 |

| Linear expansion coefficient | ISO 11359-2 | K-1 | 7E-05 | |

| Thermal Conductivity | JIS A 1412-1 | W/mK | 0.21 | |

| Specific heat | JIS K 7123 | J/g℃ | 1.5 | |

| Electrical characteristics | Surface resistance (28℃, 75%RH) | JIS K 6911 | Ω | >1E16 |

| Others | Flammability | JIS K 6911/UL 94 | HB | |

| Water absorption rateC) | JIS K 7209, A method (23℃, 24 hours) | % | 0.3 | |

| Scratch resistance | Taber abrasion (100 times) | JIS K 7204 | % | 40 |

- a) Only applicable to colorless and transparent plates.

- b) Colored boards are available at high prices.

- c) Values for 3mm thickness and 50mm square.

Application example

- Window Materials

- Building materials

- Electronic Components

- Vehicle parts, etc.

Major manufacturers

- Mitsubishi Chemical Corporation

- Sumika Acrylic Sales Co., Ltd.

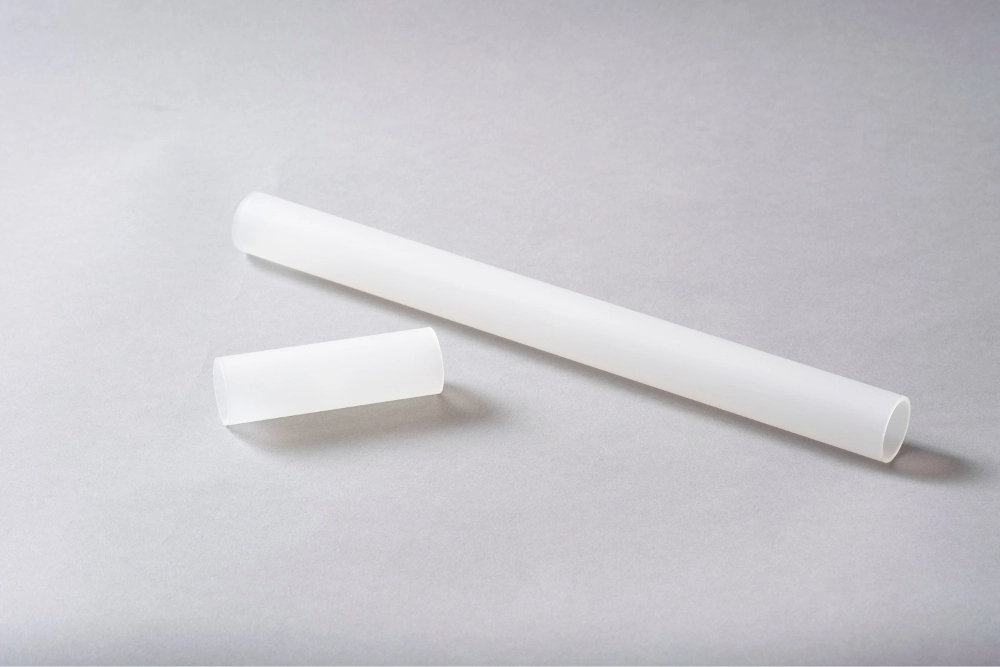

Polyvinyl chloride resin/PVC (PVC)

Polyvinyl chloride resin is one of the general-purpose plastics, and is classified as a thermoplastic resin. Its characteristics include excellent chemical resistance, flame retardancy, weather resistance, and mechanical strength, and it is widely used in various industries. It is a relatively inexpensive resin material, and can be processed in a variety of ways, such as bending, gluing, and cutting.

Features

- It is a relatively inexpensive resin.

- It has excellent flame retardancy.

- Good processability.

- Easy to bond and weld.

Physical property table

General grade plate material (excerpt from manufacturer’s data)

*Please scroll horizontally to view.

| I-500 | I-311 | I-3107 | I-3603 | I-3701 | IDH-100 | I-104 | I-1701 | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Specific gravity | – | JIS K 7112 | 1.40 | 1.45 | 1.45 | 1.45 | 1.45 | 1.40 | 1.40 | 1.40 |

| Rockwell Hardness | R scale | JIS K 7202 | 120 | 118 | 118 | 118 | 118 | 112 | 120 | 120 |

| Tensile Yield Stress | MPa (kgf/cm2) |

JIS K 6745 | 68 (691) |

63 (644) |

63 (644) |

63 (644) |

63 (644) |

56 (571) |

68 (691) |

68 (691) |

| Nominal Tensile Strain at Break | % | JIS K 6745 | 10 | 13 | 13 | 13 | 13 | 15 | 10 | 10 |

| Tensile Modulus | MPa (kgf/cm2) |

JIS K 6745 | 2500 (25500) |

2400 (24500) |

2400 (24500) |

2400 (24500) |

2400 (24500) |

2250 (23000) |

2500 (25500) |

2500 (25500) |

| Bending strength | MPa (kgf/cm2) |

JIS K 7203 | 95 (970) |

93 (950) |

93 (950) |

93 (950) |

93 (950) |

82 (840) |

95 (970) |

95 (970) |

| Flexural modulus | MPa (kgf/cm2) |

JIS K 7203 | 3300 (34000) |

3200 (33000) |

3200 (33000) |

3200 (33000) |

3200 (33000) |

2900 (30000) |

3300 (34000) |

3300 (34000) |

| Compressive strength | MPa (kgf/cm2) |

JIS K 7208 | 74 (750) |

71 (720) |

71 (720) |

71 (720) |

71 (720) |

67 (680) |

74 (750) |

74 (750) |

| Charpy impact strength | kJ/m3 (kgfcm/cm2) |

JIS K 6745 | 5.4 (5.5) |

7.4 (7.5) |

7.4 (7.5) |

7.4 (7.5) |

7.4 (7.5) |

9.8 (10.0) |

5.4 (5.5) |

5.4 (5.5) |

| Vicat softening temperature | ℃ | JIS K 6745 | 66 | 67 | 67 | 67 | 67 | 65 | 66 | 66 |

| Linear expansion coefficient | ℃-1 | JIS K 7197 | 5-7×10-5 | |||||||

| Thermal Conductivity | W/(m/K) | – | 0.15-0.16 | |||||||

| Specific heat | kJ/(kg K) | JIS K 7123 | 0.8-1.3 | |||||||

| Dimensional change due to heating | % | JIS K 6745 | ±4% or less | |||||||

| Heat resistance | – | JIS K 6911 | self-extinguishing | |||||||

| UL94 | V-0 | |||||||||

| Volume resistivity | Ωcm | JIS K 6911 | 1015 and above | |||||||

| Withstand voltage | kV/mm | JIS K 6911 | 25-35 | |||||||

| Water absorption rate | % | JIS K 7209 | 0.02-0.03 | |||||||

| Total light transmittance | % | JIS K 7105 | >85 | – | – | – | – | >80 | – | – |

| Tone | – | – | Clear | White | White | Grayー | Black | Clear | Brown Smoke |

Gray Smoke |

- *The values in the table above are measured values and are not guaranteed values.

Application example

- Electrical Insulation Materials

- Piping

- Auto Parts

- Home appliance parts

- Daily necessities etc.

Major manufacturers

- Takiron C.I. Co., Ltd.

- Sekisui Plastics Co., Ltd.

If you have any other grades, shapes (pipes/round bars), manufacturer specifications, etc., please contact us separately.