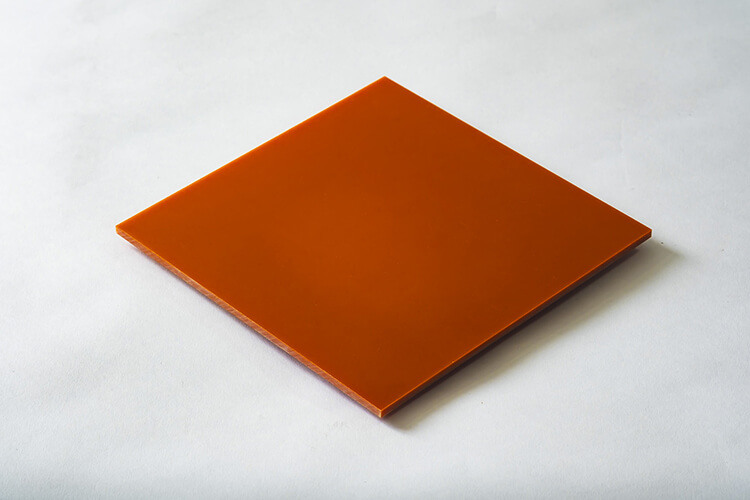

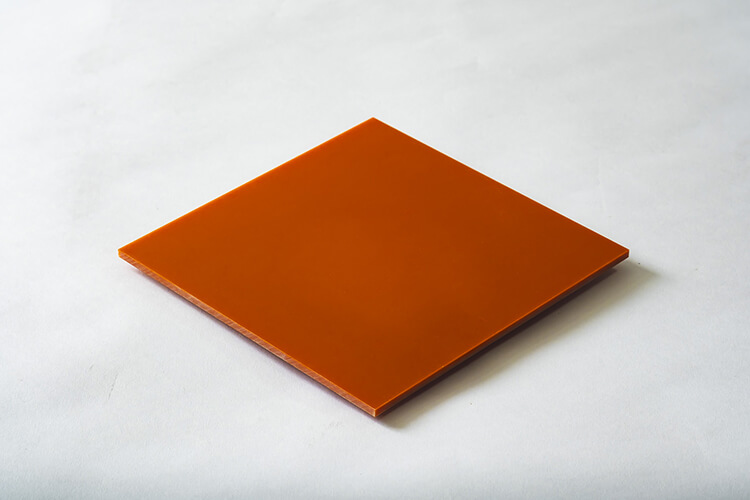

Bakelite (paper/cloth)/phenolic resin

(JIS standard: PL-PEM/PL-PEV)

Paper Bakelite is one of the engineering plastics, and is classified as a thermosetting resin.

It is a laminated board with paper as the base material and hardened with phenolic resin. It is a versatile insulating material, inexpensive, and easy to machine.

Taking advantage of its mechanical strength, heat resistance, and electrical insulation properties, it is widely used in fields such as semiconductors and insulating materials.

If the purpose is electrical insulation, we recommend paper bakelite, and if the purpose is impact resistance, we recommend cloth bakelite.

It is a cheaper material compared to cloth.

Features

- Excellent mechanical strength

- Excellent electrical insulation

- Excellent heat resistance

Product lineup

Bakelite Paper

FL-102 (PL-PEM)

FL-102 is a paper-based phenolic resin laminate that has excellent heat resistance, abrasion resistance, insulation, and chemical resistance. It is easy to process and is widely used in the manufacture of machine parts and electrical equipment. It complies with the Food Sanitation Act and the revised Food Sanitation Act.

FL-100 (PL-PEV)

It has excellent electrical properties such as withstand voltage and is easy to process. It is a high-voltage product that is a higher grade than PL-PEM.

Bakelite Fabric

PCP-463 (PL-FLE)

This is the most standard laminate used in electrical and electronic equipment parts, and is highly easy to process.

Physical property table

- FL-102 (PL-PEM)

- FL-100 (PL-PEV)

- PCP-463(PL-FLE)

-

FL-102 (PL-PEM)

*Please scroll horizontally to view.

Material Type Paper-based phenolic resin JIS standard PL-PEM ANSI standard (XX) UL standard 94 H B Part number FL-102 Through-layer voltage resistance in oil MV/m C-90/20/65 No destruction 15OK(13OK) Layer withstand voltage in hot oil kV C-90/20/65

+D-2/100No destruction 9OK(8OK) Insulation resistance normal condition MΩ C-90/20/65 5×10³-10⁶(5×10²) after boiling C-90/20/65

+D-2/1003×10-5×10²(10) Volume Resistivity normal condition MΩ-cm C-90/20/65 10⁵-10⁷ after moisture absorption treatment C-90/20/65

+C-96/40/9010⁴-10⁶ Surface resistance normal condition MΩ C-90/20/65 10⁵-10⁷ after moisture absorption treatment C-90/20/65

+C-96/40/9010⁴-10⁶ Dielectric constant normal condition – C-90/20/65 4.0-6.0 after water immersion C-90/20/65

+D-24/234.5-6.5 Dielectric loss tangent normal condition – C-90/20/65 0.030-0.050 after water immersion C-90/20/65

+D-24/230.035–0.055 Bending strength Perpendicular to layer LW MPa A 120-200(98) CW 110-180(98) Izod Parallel to layer J/cm A 0.21–0.40(0.20) Cleavage strength kN A 3.9-6.4(3.4) Water absorption rate % E-24/50

+D-24/233.0mm 0.60-0.80(1.30) 10.0mm 0.20-0.35(0.55) Appearance after heating Heat for 2 hours – A 130℃ No abnormalities (130℃±2) Specific gravity – A 1.31-1.35(1.25-1.50) Acetone resistant (boiled for 30 minutes) – A No abnormalities Rockwell Hardness M scale – A 110±10 -

FL-100 (PL-PEV)

*Please scroll horizontally to view.

Material Type Paper-based phenolic resin JIS standard PL-PEV ANSI standard (XXX) UL standard 94 H B Part number FL-100 Through-layer voltage resistance in oil MV/m C-90/20/65 No destruction 18OK(16OK) Layer withstand voltage in hot oil kV C-90/20/65

+D-2/100No destruction 10OK(8OK) Insulation resistance normal condition MΩ C-90/20/65 10⁴-10⁶(5×10³) after boiling C-90/20/65

+D-2/1005×10-5×10³(50) Volume Resistivity normal condition MΩ-cm C-90/20/65 10⁵-10⁷ after moisture absorption treatment C-90/20/65

+C-96/40/9010⁴-10⁶ Surface resistance normal condition MΩ C-90/20/65 10⁵-10⁷ after moisture absorption treatment C-90/20/65

+C-96/40/9010³-10⁵ Dielectric constant normal condition – C-90/20/65 4.5-6.5 after water immersion C-90/20/65

+D-24/235.0-7.0 Dielectric loss tangent normal condition – C-90/20/65 0.030-0.050 after water immersion C-90/20/65

+D-24/230.040-0.060 Bending strength Perpendicular to layer LW MPa A 108-167(88) CW 98-137(88) Izod Parallel to layer J/cm A 0.20-0.35(0.15) Cleavage strength kN A 4.4-6.9(2.9) Water absorption rate % E-24/50

+D-24/2310.0mm 0.28-0.33(0.45) Appearance after heating Heat for 2 hours – A 130℃ No abnormalities (130℃±2) Specific gravity – A 1.33-1.38(1.25-1.50) Acetone resistant (boiled for 30 minutes) – A No abnormalities Rockwell Hardness M scale – A 105-120 -

PCP-463(PL-FLE)

*Please scroll horizontally to view.

Part number PCP-463 Appearance color Primary colors Substrate and Resin String and thread cloth Phenol Through-layer breakdown voltage MV/m C-90/20/65 11-15 Linear Breakdown Voltage kV/6mm O-0.5/90 8-15 Insulation resistance MΩ C-90/20/65 103-105 C-90/20/65

D-2/1005×101-102 Dielectric constant – C-90/20/65

(1MHz)5.5-7.0 Dielectric loss tangent – C-90/20/65

(1MHz)0.08-0.10 Bending strength MPa A,FW-LW 140-180 A,FW-CW 90-140 Tensile strength MPa A,LW 70~100 A,CW 50-80 Compressive strength MPa A,FW 260-330 A,EW 180-230 Impact strength (Izod) J/cm A,EW-CW 0.8-1.3 Impact strength (Charby) J/cm² A,FW – Cleavage strength kN A 9.0-12.0 Appearance after heating ℃ 2hr 140 Specific gravity – A 1.30-1.40 Compressive creep properties % 180℃-10MPa

(200hr)– Thermal expansion coefficient 1/℃ A,FW – Thermal Conductivity W/(m K) A,FW – Young’s modulus (tensile modulus of elasticity) GPa LW – Compressive modulus GPa FW – Poisson’s ratio – – – Specific heat J/(g K) – – Reference standard JIS K 6912 PL-FLE NEMA LE MIL FBE

Purpose

- Switchboard

- Transformers

- Insulating terminal block

- Insulating materials for vehicles, etc.

Major manufacturers and JIS

- Futamura Chemical Co., Ltd.

- PL-PEM/PL-PEV